Contamination Issues in Generic Drugs: Recent Cases and How to Prevent Them

Dec, 25 2025

Dec, 25 2025

Generic drugs save Americans billions every year-over $1.7 trillion in the last decade alone. But behind the low price tag is a growing crisis: contamination in generic medications is no longer rare. It’s systemic. And it’s putting lives at risk.

What’s Going Wrong in Generic Drug Manufacturing?

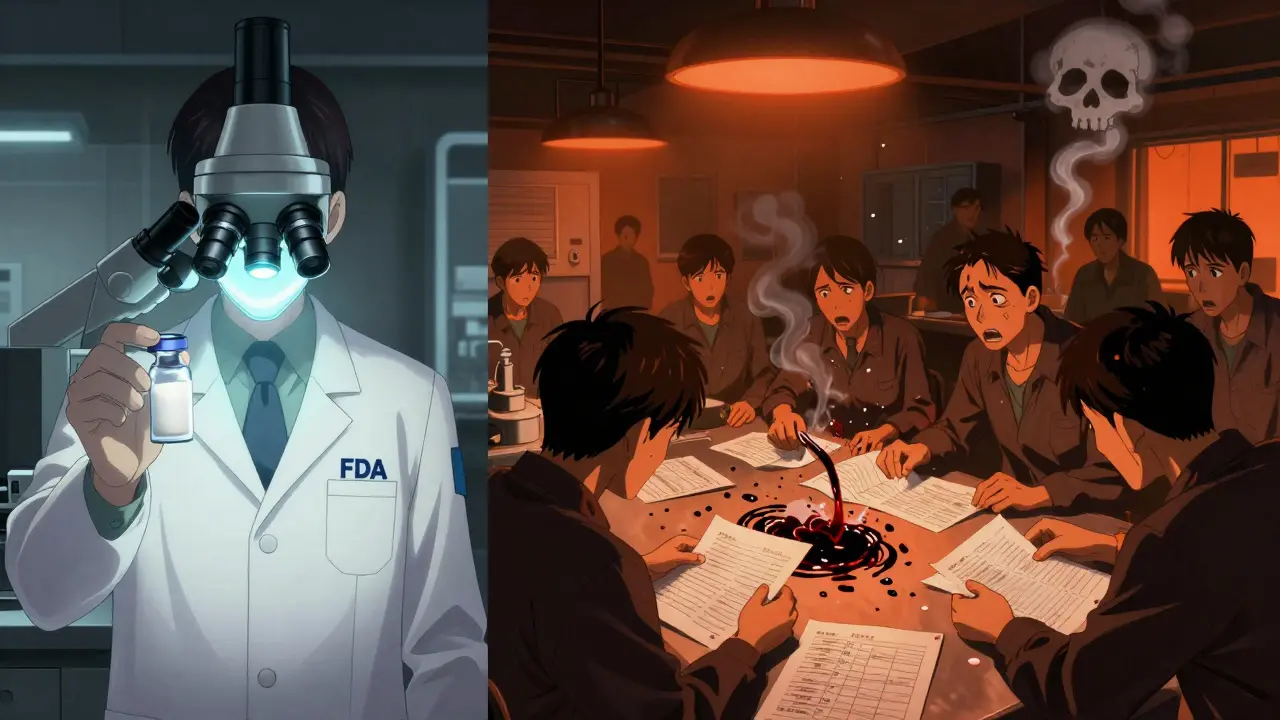

Generic drugs aren’t copycats-they’re supposed to be exact matches to brand-name drugs in active ingredients, strength, and performance. But between 2018 and 2025, over 8,000 drug recalls were issued in the U.S., and nearly 40% of them were tied to contamination. The problem isn’t random. It’s structural. The core issue? Cost-cutting at foreign manufacturing plants. India and China produce the vast majority of the active pharmaceutical ingredients (APIs) and finished generic pills sold in the U.S. India makes 40% of all finished generic drugs here. China supplies 80% of the raw ingredients. But inspections? The FDA only checks about 13% of Indian facilities each year, even though they’re responsible for nearly half the generics on U.S. shelves. When manufacturers skip proper testing, use unapproved chemicals, or destroy quality records, contamination happens. And it’s not always obvious. Patients take these pills daily for years-until something goes wrong.Recent Cases That Shook the System

One of the biggest scandals involved Valsartan, a blood pressure drug. Between 2018 and 2025, batches from Zhejiang Huahai Pharmaceutical in China were found to contain NDMA, a known carcinogen. Some samples had levels 200 times higher than the FDA’s safe limit of 96 nanograms per day. Patients who took these pills for years saw their cancer rates jump. Colorectal cancer cases among exposed users were nearly seven times higher than in the general population. Over 1,300 lawsuits are now active, with victims reporting diagnoses within five years of exposure. Then there’s Mucinex. In 2025, independent lab tests found benzene in some generic versions sold at Walgreens. Benzene is a known cause of leukemia. The FDA’s limit is 2 parts per million (ppm). Some samples hit 4.7 ppm. Two women in the lawsuit reported developing bone marrow damage after using the product for 18 months. The drug wasn’t recalled immediately. It took a lawsuit to force action. In oncology, the stakes are even higher. A 2025 STAT News investigation tested 17 chemotherapy drugs from Indian manufacturers. Twelve of them contained less than 80% of the labeled active ingredient-far below the FDA’s acceptable range of 85-115%. One hospital reported that 7 out of 11 cancer patients on a contaminated batch of cisplatin saw their tumors grow instead of shrink. Treatment failure rates doubled compared to patients on verified brand-name versions. And then there are the fentanyl patches. Between 2002 and 2025, over 52 million patches were recalled due to seal failures. In one 2023 recall by Sandoz, 0.8% of patches leaked more than 15% of their intended dose. That’s enough to kill someone who didn’t need that level of opioid. Emergency rooms saw spikes in overdoses linked to these faulty patches.Why Do These Problems Keep Happening?

It’s not just bad actors. It’s a broken system. The FDA’s inspection system is overwhelmed. With 28,000 foreign drug facilities needing review and only $78 million in its 2025 budget for inspections, the agency can’t keep up. In 2024, only 62% of pharmacies could even verify if a drug’s supply chain was legitimate under the Drug Supply Chain Security Act. That law was supposed to be fully operational by 2027. We’re not even halfway there. Manufacturers in countries like India have been caught shredding quality records, pouring acid on documents, and falsifying test results. Zee Laboratories, one of the worst offenders, has been cited 46 times since 2018. In 2024, inspectors found visible particles in every single vial of cisplatin they sampled. Even worse, the FDA has long hidden the names of drugs tied to contaminated facilities in its inspection reports. That meant doctors and pharmacists couldn’t tell which batches were risky. Patients had no way to know if their prescription was safe. Only in September 2025 did the FDA announce it would stop redacting drug names-a move that came after years of pressure from ProPublica and patient advocates.

Who’s Paying the Price?

It’s not just the patients. Pharmacists are spending 22% more time checking recall lists and verifying sources. Hospitals are stocking extra brand-name drugs just in case generics fail. Oncology centers are delaying treatments because they can’t trust the supply. One Reddit user, PharmTech2020, wrote in March 2025: “I’ve seen three different batches of generic levothyroxine fail potency testing in six months. Patients’ TSH levels went wild until we switched back to brand.” That’s not an outlier. It’s becoming routine. Patients aren’t just getting sick-they’re dying. And lawsuits are piling up. The Valsartan cases alone could cost manufacturers over $1 billion in settlements. The generic industry is projected to lose $4.3 billion annually to recalls by 2027. But money doesn’t bring back lives.How Can We Prevent This?

There are solutions-but they require real commitment, not just announcements. Continuous manufacturing reduces contamination risk by 78%, according to MIT. But it costs $5-15 million to upgrade a plant. Most foreign manufacturers won’t spend that unless forced. Process Analytical Technology (PAT) lets factories monitor drug quality in real time. Only 37% of foreign plants use it. The FDA’s 2023 update to its Pharmaceutical Quality initiative pushed for this, but enforcement is weak. Blockchain-based supply chains could track every pill from raw ingredient to pharmacy shelf. The FDA’s 2026-2030 plan includes this-but it’s still in pilot stages. Pharmacists and doctors need full transparency. That means public, searchable databases of every recall, every inspection, every violation-with the drug name, manufacturer, and batch number clearly listed. No more hiding. And manufacturers need teeth behind the rules. Fines aren’t enough. If a company destroys quality records, it should lose its license to sell in the U.S. permanently. No second chances for life-threatening negligence.

What Should You Do as a Patient?

You can’t control the factory. But you can protect yourself.- Check the FDA’s drug recall list weekly. Bookmark it. Set a reminder.

- If your generic drug suddenly stops working-your blood pressure spikes, your thyroid levels go haywire, your pain returns-ask your pharmacist: “Is this batch under recall?”

- Ask your doctor: “Can I get the brand-name version if the generic fails?” Many insurers will cover it if you document the issue.

- Report side effects. Use the FDA’s MedWatch program. One report might be the warning that stops a dangerous batch from reaching thousands.

What’s Next?

The FDA’s new “Name Transparency Initiative” is a start. The GDUFA III rules requiring real-time stability testing for high-risk drugs like chemotherapy are promising. But without independent audits, mandatory recalls within 48 hours of contamination detection, and real penalties for falsifying data, this will keep happening. The Valsartan multidistrict litigation’s first test trials are scheduled for September 2025. If courts find manufacturers knew about NDMA risks as early as 2012-and hid it-that could set a precedent that changes the entire industry. For now, the message is clear: cheap drugs shouldn’t mean dangerous drugs. And if the system won’t fix itself, patients and providers must demand change.Are all generic drugs unsafe?

No, not all generic drugs are unsafe. The vast majority are safe and effective. But contamination issues have become more frequent, especially in drugs manufactured in certain foreign facilities. The problem isn’t with generics as a category-it’s with poor oversight and cost-cutting in specific factories. Always check FDA recall notices and report any unusual side effects.

How do I know if my generic drug was recalled?

Check the FDA’s official drug recall page regularly. You can search by drug name, manufacturer, or lot number. Your pharmacist should also notify you if your prescription is recalled, but don’t rely on them alone. Keep the original packaging and note the lot number. If you’re unsure, call the manufacturer’s customer service line listed on the bottle.

Can I ask for the brand-name version instead?

Yes. If you’ve had problems with a generic version-like inconsistent effects or side effects-ask your doctor to write “Dispense as Written” or “Brand Necessary” on the prescription. Many insurers will approve the brand-name drug if you document the issue. This is especially important for drugs like levothyroxine, blood thinners, and chemotherapy.

Why aren’t more foreign drug plants inspected?

The FDA simply doesn’t have enough staff or funding. There are over 28,000 foreign drug facilities that need inspection. The agency’s 2025 budget allowed for only 1,200 inspections-mostly focused on the highest-risk facilities. India and China produce most of the U.S.’s generics, but only 13% of Indian plants are inspected annually. Until Congress increases funding and mandates more frequent audits, the gap will remain.

What should I do if I think my medication is contaminated?

Stop taking it immediately. Contact your doctor and pharmacist. Save the bottle and packaging-including the lot number. Report it to the FDA through MedWatch (https://www.fda.gov/safety/medwatch-fda-safety-information-and-adverse-event-reporting-program). If you’ve experienced serious side effects, consider consulting a lawyer. Many contamination cases now lead to class-action lawsuits, and your report could help others.

Becky Baker

December 25, 2025 AT 17:33This is why I refuse to touch anything made in China or India anymore. My grandma died because her blood pressure med had crap in it. We’re letting foreign factories poison our people just to save a few bucks. Enough is enough.

Natasha Sandra

December 27, 2025 AT 13:54Ughhh I literally cried reading this 😭 I’ve been on generic levothyroxine for years and my TSH has been all over the place. I switched back to Synthroid last month and I feel like a new person. 🙏 Please, please check your meds, everyone. Your life matters.

Erwin Asilom

December 29, 2025 AT 06:08The data presented here is alarming but not surprising. The FDA’s inspection regime is structurally inadequate given the scale of global pharmaceutical production. Without mandatory real-time quality monitoring and enforceable penalties for record destruction, systemic failure is inevitable. The solution requires regulatory modernization, not just public awareness.

Sumler Luu

December 29, 2025 AT 19:51I work in a hospital pharmacy. We’ve had to pull three different generic batches in the last six months. No one tells you this stuff. Patients assume the FDA has their back. They don’t. I wish we could just label the dangerous ones with a red flag.

Brittany Fuhs

December 31, 2025 AT 16:26It’s pathetic. We outsource the most critical part of our healthcare to countries that don’t even have the same ethical standards. We’re not just being cheap-we’re being stupid. And now people are dying because we let corporations prioritize profit over human life. Shame on us.

Sophia Daniels

January 2, 2026 AT 14:21Let me get this straight: we’re letting Chinese factories dump carcinogens into our blood pressure meds, Indian labs serve up chemo with half the active ingredient, and the FDA just shrugs? This isn’t negligence-it’s state-sanctioned murder. And they wonder why people are losing trust in medicine? 🤡

Nikki Brown

January 3, 2026 AT 22:30I’m so tired of this. I’ve had two relatives die from side effects tied to generics. No one talks about it. The system is broken, and the people who suffer are the ones who can’t afford to fight back. I just want to know: who’s going to pay for the funeral bills?

Peter sullen

January 5, 2026 AT 06:35It is imperative to note, in light of the aforementioned systemic deficiencies, that the current regulatory architecture-predicated upon reactive, rather than proactive, quality assurance mechanisms-is fundamentally misaligned with the risk profile of pharmaceutical manufacturing. Without the implementation of blockchain-enabled traceability, coupled with mandatory PAT adoption, the probability of recurrent contamination events remains statistically intolerable.

Steven Destiny

January 5, 2026 AT 21:39Enough is ENOUGH. If you’re a CEO at a generic drug company and you’re shredding lab reports or hiding contamination, you should be in prison-not collecting bonuses. I’m done pretending this is just a ‘business issue.’ This is terrorism against the sick.

Fabio Raphael

January 7, 2026 AT 21:23It’s heartbreaking to read this and think about all the people who just took their meds every day, trusting it was safe. I’ve seen patients cry when they find out their meds were contaminated. We owe them more than just recalls-we owe them accountability.

Amy Lesleighter (Wales)

January 8, 2026 AT 06:15cheap meds dont mean bad meds. but when the factory lies? then its on us to speak up. check your lot numbers. talk to your pharmacist. dont stay quiet.

Rajni Jain

January 8, 2026 AT 10:19as someone from india, i’m so sorry. not all factories are like this, but yes, some are. we need better rules here too. i work with a small lab that tests every batch-no shortcuts. but we’re the exception. please don’t hate us, just help fix the system.